When finding versatile and resilient solutions for our homes’ exterior, pressure treated wood often stands out as a go-to choice. Known for its enhanced durability and innate resistance to the ravages of weather and time, it is widely used for various outdoor projects.

However, even this wonder of engineering has its kryptonite – rot. While naturally more resistant to decay, pressure treated wood is not completely immune to rotting. But fear not. In this blog, we’ll guide you through some effective strategies to prevent your pressure treated wood from rotting. Thereby enhancing its lifespan and keeping your outdoor projects sturdy and looking great for years to come. Let’s explore this journey of preservation together.

What is Pressure Treated Wood?

Pressure treated wood refers to lumber that’s been placed in a depressurized holding tank and infused with preservatives to protect it from insects, rot, and decay. The process involves vacuum and pressure cycles to force deep penetration of the preservatives into the wood.

This treatment method results in a product that’s robust, more resilient to the harshness of the outdoors, and prone to less damage from insects or moisture. Whether constructing a deck, installing a mailbox, or even setting up a playground, pressure treated wood can make for a robust and durable choice.

What is the Difference Between Pressure Treated Wood and Regular Wood?

Here’s a comparison between pressure treated wood and regular wood:

• Pressure-treated wood, as we mentioned earlier, is lumber that has undergone a process involving a depressurized holding tank and a mix of chemicals, including metallics. This treatment enhances its resistance against rotting, damage from various weather elements and insects. It is often used in outdoor construction projects like wood decks due to its increased resilience.

• On the other hand, regular wood, or untreated wood, has not undergone any chemical treatment. It is often used for indoor applications such as cabinets, furniture, and items that will be painted or stained. Some types of untreated wood have naturally occurring attributes that may make them resistant to rot and insects. But overall, they don’t have the same level of durability against outdoor elements as pressure-treated wood.

It’s important to choose the right type of wood based on its intended use. Pressure-treated wood is suitable for outdoor settings and projects exposed to the elements. At the same time, untreated wood can be used for a broader range of indoor applications.

How Long Does Pressure Treated Wood Last Before It Rots?

On average, pressure treated wood can last anywhere from 10 to 20 years, sometimes even longer, with proper care and maintenance. However, its durability depends heavily on the environmental conditions it is exposed to. This longevity is attributed to the chemical preservatives used during the treatment process that help resist infestation and slow down the decay process significantly.

Even so, like all wood types, pressure treated wood is still susceptible to natural wear and tear, and without proper care or in excessively harsh conditions, it can still rot.

How To Stop Pressure Treated Wood From Rotting

Treated wood or pressure treated wood looks great, is easy to work with, and it’s long-lasting. Occasionally we overlook it and forget about it once we have it installed. Pressure treated wood is used for fences, posts, decks, and picnic tables. But a lot of people wonder — does pressure treated wood rot? Most people think this material is completely resistant to rot and termite infestations. This is not always the case. Sure, pressure treated wood will last longer than untreated wood. But that doesn’t mean that fungus can’t attack it, especially in the wet seasonal conditions that occur in Toronto. Read on to learn about does pressure treated wood rot and how you can prevent it!

1. Why Does Pressure Treated Wood Rot?

• The answer to does pressure treated wood rot is yes. Any pressure treated wood rot is usually due to a fungal issue. The fungi that cause this are very small organisms that move into the wood and feed on it over time. This causes the pressure treated wood to decay and soften, which then turns into rot. All kinds of fungal issues basically create the same problem: rot.

• Fungi or fungal spores usually affect wet wood. The easiest way to stop the damage they do is simple: keep your pressure treated wood dry. When dry wood is affected, brown-rot fungi are to blame. This type of fungus does not need much moisture to grow. In general, dry pressure treated wood is less likely to rot and, in the event of rot, can be more easily repaired than wet rotted treated wood.

• The brown-rot fungus occurs most commonly in birch wood and will look like an uneven pattern or brick-like cracking. Remember that although treated wood is protected by chemicals, pressure treated wood rotting is a physical change that will occur when microorganisms in the air affect wet or dry wood.

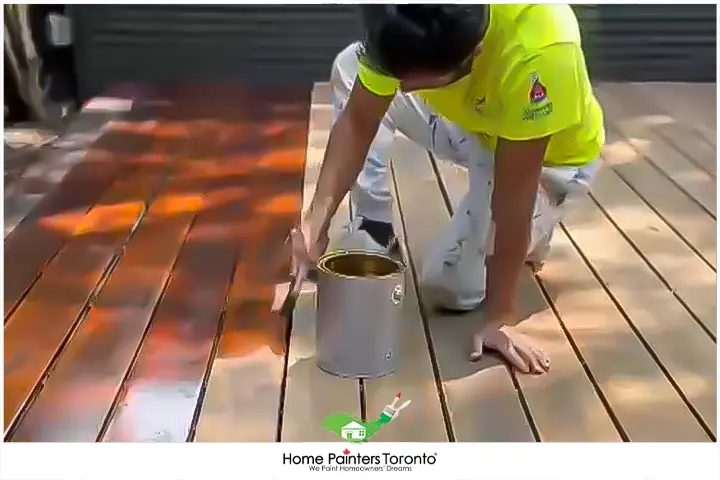

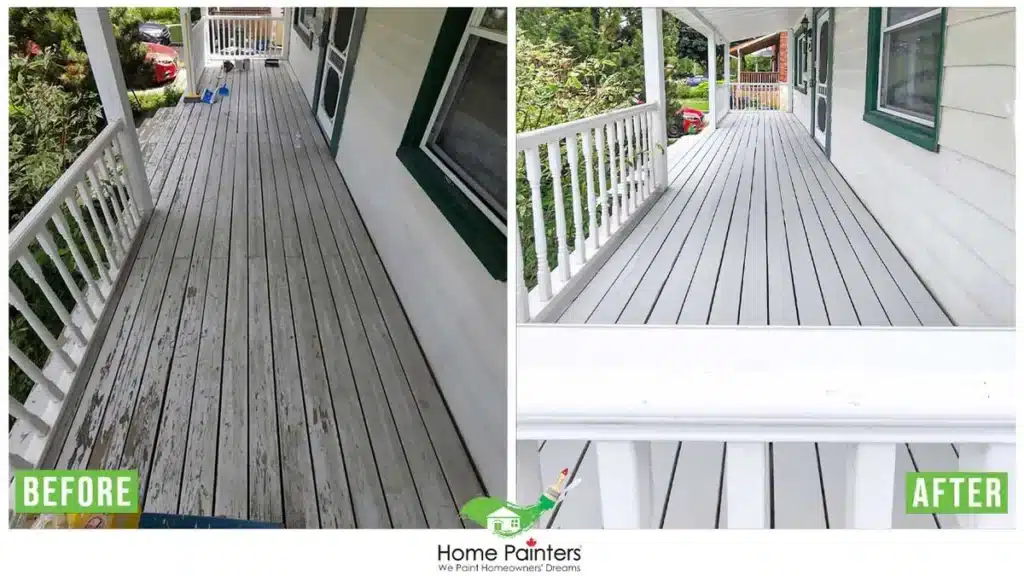

Amazing Deck Transformations

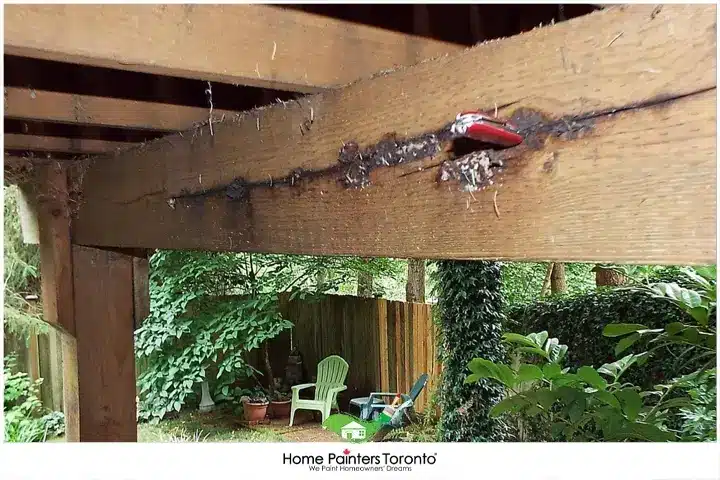

2. The Typical Places to Check for Rot

Sometimes wood rot isn’t so apparent to the naked eye. When you do your yearly inspection, actively look for rot on the wood. If you suspect that a spot might be rotting out, use your fingers to press on the wood. Something is going on if they feel soft or crumble easily to the touch. Some typical spots to inspect are:

- • Deck support posts or beams

- • Where two pieces of trim meet

- • Surfaces such as exterior window sills and railings

- • Exterior wood stairs (especially at the base or towards the bottom)

- • Where wood siding meets the trim

3. How Can I Prevent Treated Wood Rot?

- • To prevent any kind of pressure treated wood rot, you should keep it coated in paint, oils, varnishes, protecting spray, waxes or any other kinds of substance that will enhance the longevity of your treated wood.

- • Pressure treated wood can crack and split from water exposure, allowing fungi to get into the cracks and create wood rot. If you have a pressure treated deck, this can be a harder problem to avoid. The best way to protect from pressure-treated wood rot is to apply a deck preservative. As mentioned earlier, stains, paints and sealants are the best choices. You can find these items easily at the local hardware store. Some of these protectors can also contain a fire retardant, which can be useful and help keep you and your family safe.

- • Although a sealant provides effective resistance to moisture damage (which leads to rot), you will need to apply it periodically, at least once a year. None of these products will offer lifetime protection, though. A higher-grade sealant will result in longer protection, but the cost can be a factor. Inspect your treated wood for signs of wear and tear, and keep it coated. Doing so will stop your treated wood from rotting!

4. Can I Paint Pressure Treated Wood?

A popular question that a lot of people have is if they can even paint pressure treated wood. The answer is yes, but it is slightly complicated.

If you just recently received your wood from the hardware store or your local lumber supplier, it will definitely need some time to dry out before painting. You can do a water test to see and if the water absorbs into the surface, it’s ready for paint.

Also, it’s important to think about what kind of paint you’re going to use on your pressure treated wood. Our expert recommendation is to use an exterior latex base paint (vs. an oil-based paint).

One more question that piques the interest of homeowners is, “Does paint stop wood from rotting?”

Paint can help prevent wood rot by acting as a protective barrier between the wood and moisture, which is one of the main causes of wood rot. A fresh coat of paint keeps the area dry and reduces the chances of wood rot spreading if left untreated. However, proper preparation and maintenance, like priming all six sides of the wood and ensuring water is not allowed to pool or seep through cracks in the paint, are essential for effectively preventing wood rot.

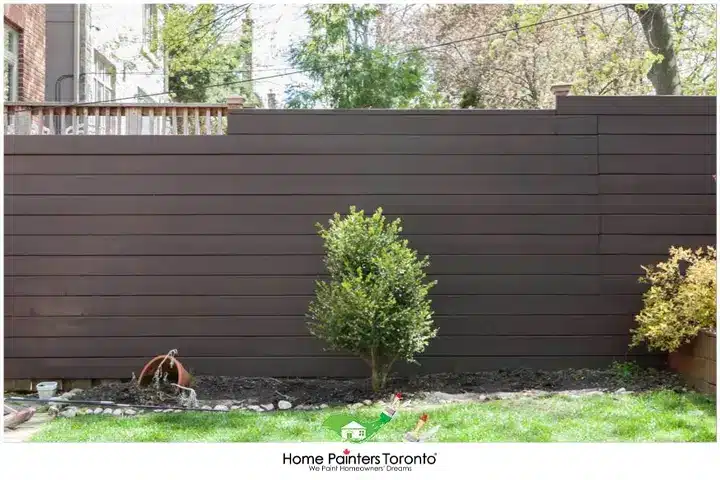

Exterior Paint Colours for Fence Painting

If you’re starting from scratch and need to figure out what kind of paint to use on your fence, it’s great to start with oil-based paint. Behr’s Premium Plus Exterior Oil-Based Primer & Sealer is dependable. If you want to go the latex route, try out Sherwin Williams Exterior Latex Wood Primer.

As far as exterior painting colours go, white fence painting will be big in the 2021 season. So, be sure to check out White Diamond. Also, if you want something modern that won’t show the dirt as well, grey is another big colour for fence painting as well. Thundercloud Gray is a pretty mid-tone gray that will brighten up any yard.

Tips on How to Prevent Wood From Rotting Outside

- • Seal Your Wood: While pressure-treated wood is resistant to rot, it’s still susceptible to moisture. One of the factors contributing to what destroys pressure treated wood is moisture. Sealing the wood with a moisture-repelling sealant prevents water from entering and reduces the chances of rotting.

- • Regular Maintenance: Regularly check for any signs of rot or decay, especially in damp areas or with less sun. Early identification can prevent extensive damage.

- • Proper Installation: Ensure the wood isn’t in continuous contact with the ground or water-tended areas unless rated for such use.

- • Allow the Wood to Dry before Staining or Painting: After purchasing pressure treated wood, give it time to dry out before applying any paint or stain.

- • Use High-quality Paints and Stains: To protect your wood structure adequately, opt for high-quality, outdoor-rated stains or paints for pressure treated wood.

- • Promptly Address Exposed Areas: If there are screw or nail holes or any other form of exposed wood, promptly take care of them.

What Are the Advantages and Disadvantages of Pressure Treated Wood?

Advantages

- • Affordability: Pressure treated wood is often cheaper than other varieties, making it a cost-effective choice for various projects.

- • Durability: The process of pressure treating makes the wood more resistant to rot, water damage, and insect infestation, leading to a longer lifespan.

- • Ease of Availability: Pressure treated wood is generally available in abundance since it is made from fast-growing wood species like pine.

- • Protection from the Elements: Pressure treated wood can withstand changing weather conditions due to its chemical protection, leading to a longer life of about 20 years.

Disadvantages

- • Splinters and Checking: As a natural wood product, pressure treated wood inevitably develops splinters over time.

- • Limited Applications: Some types of pressure treated wood are unsuitable for all applications, as they may have low-level leaching of chemicals and could lead to potential health risks when used indoors.

- • Environmental Concerns: While effective, the chemicals used in the treatment process might raise environmental concerns and may not be suitable for eco-conscious consumers.

With these points in mind, it’s essential to weigh the advantages and disadvantages when deciding whether to use pressure treated wood for a particular project.

More Interesting Blogs Related to

“HOW TO STOP PRESSURE TREATED WOOD FROM ROTTING”

The beauty of your home can rely on knowing how to stop treated wood from rotting. With the tips mentioned above, you should be able to do just that and save money in the future. However, if you have already noticed pressure treated wood rot or you don’t have the time to invest in protecting it yourself, allow our home painting services to take over! Give HPT a call, and we’ll happily do it all for you! Call us NOW at 416-494-9095 or email [email protected]! And don’t forget to follow us on our social media accounts below.